Powder coating

More on powder coating V coat

Applications powder coating

Standard is the technique of metal powder coating. V coat is not only strong in aluminum powder coating or powder coating of steel. Stainless steel powder coating is certainly also one of our specialties.

V coat also handles the powder coating of many stainless steel and metal products from our sister company Robby metal construction.

So V coat is definitely not a standard paint shop and has a custom powder coating technique for every material.

In our workshop there are two powder coating lines, and we have a very modern powder coating plant in which we can treat pieces up to an area of 3950x950x1500mm.

V coat - Powder lacquer street 1

Powder coating line with an extensive chemical pre-treatment line for various materials such as steel, zincor, sendzimir, hot-dip galvanised, laser-coated sheet, aluminium, cast aluminium, zamak and stainless steel. This line features a very modern rapid colour change cabin with 8 automatic spray guns and is suitable for both small and large series.

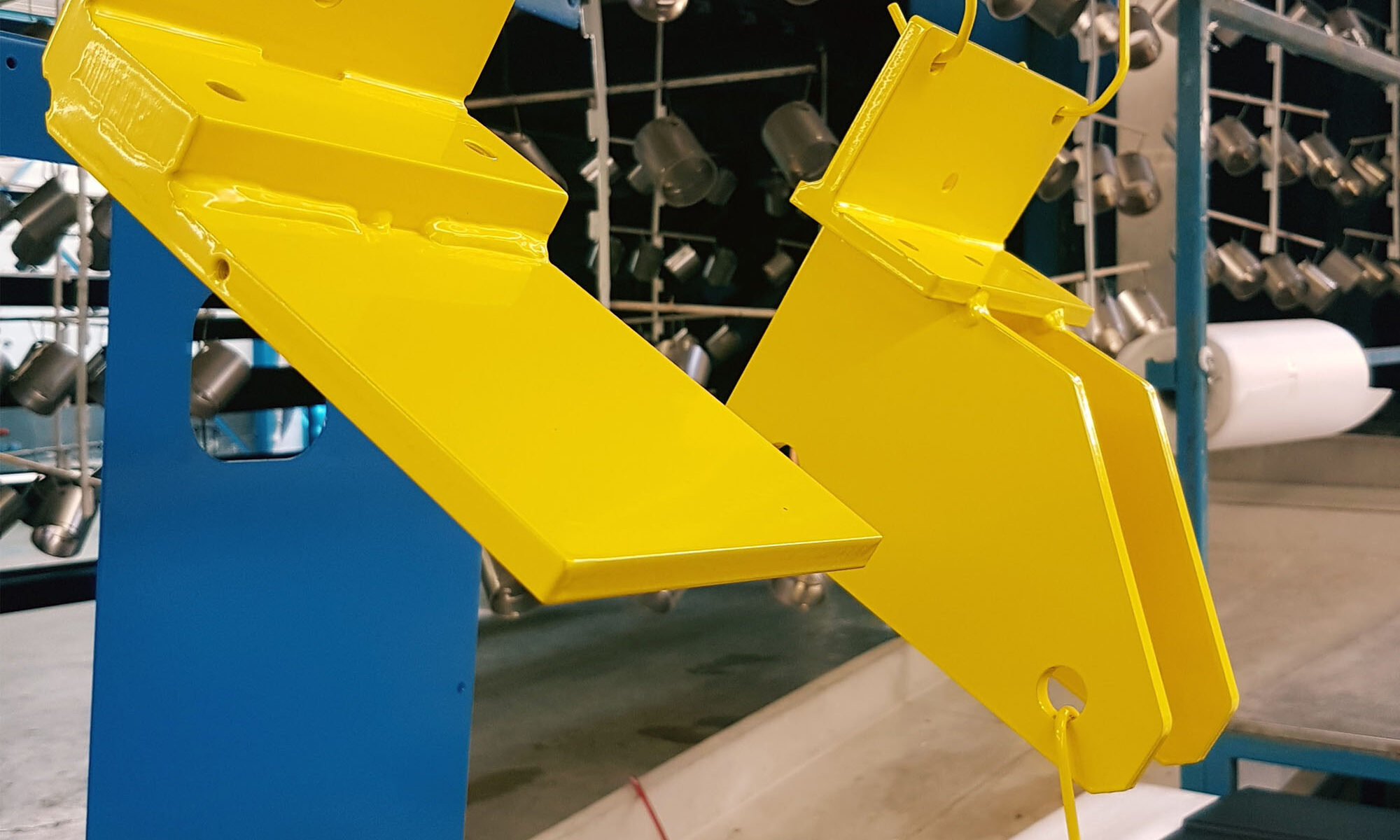

V coat - Powder lacquer street 2

On this powder coating line, very large pieces (6x2x2 m) can be powder coated with a very high quality finish. This is because the coating line is equipped with an integrated blast and powder cabin and baking oven.

Other services

Wet coating

V coat is your partner for wet painting on all kinds of materials, from ferrous & non-ferrous to plastics. We offer a solution for every application, both small and large series. With us you are in the right place: anything goes!

Printing

V coat has a wide range of options in surface treatment techniques and therefore also in printing. As a final finish, we can also print or print on your coated products or painted parts. V coat provides a total solution through various in-house printing techniques.

Pretreatment

The quality of powder or wet-lacquer coating stands or falls with proper and thorough pre-treatment of the materials. Only then will you get an even, scratch-resistant and beautiful end result.

EMI shielding

Electronic products receive a lacquer that ensures protection against external electromagnetic interference.

Assembly

V coat unburdens you as much as possible by also providing small assembly works, thus streamlining your process.